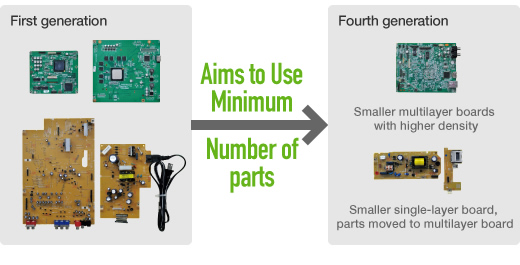

We product deliver such superior cost performance stems from the attention they are given at the design stage. We have brought the core components by in-house made, reduced the number of components and analyzed its value of parts and materials. We have made efforts such as decreased the number of production processes and shifted the management of main design processes to offshores. These cost down efforts have enabled us to win out amid stringent cost competition and become a leading provider of products at reasonable prices.

We have introduced the unique Funai Production System (FPS) at our factories. This system creates placing stresses intentionally on the production line, such as by increasing the speed of the conveyer. We then observe the problems that arose as a result and improve on conditions that caused the failure. Repeating this cycle enables us to achieve ongoing productivity increases.

Plant in Thailand

Plant in Thailand

Plant in the Philippines (Cebu)

Plant in the Philippines (Cebu)

We concentrate its production facilities in the most appropriate locations and enhance cost competiveness by procuring materials locally. Particularly in recent years, within Asia there has been a marked trend toward boosting production capacity in Thailand, owing to worker shortages and rising labor costs in China.We have started to manufacture inkjet printers in the new factory on the Philippine island of Luzon.

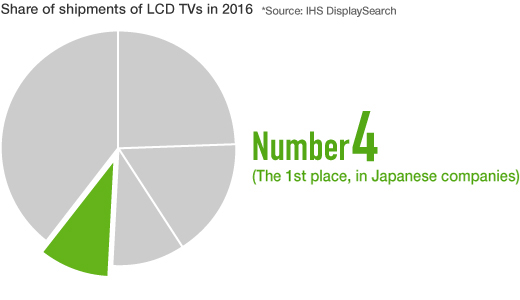

In LCD TVs, we boast the fourth place of the ranks for the North American market—one of the world's largest. However, we aim for sales to be regionally balanced and not place undue reliance on North America. As a result, we are reinforcing our operations in the European and Japanese markets, and open up in Mexico and other Latin American countries, and such emerging markets as India and Thailand.